IBR Roof Sheet Roll Forming Machine

For More information, Delivery Time And Prices, Please Mail Us!

Product Overview

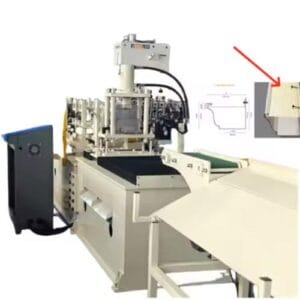

The IBR Roof Sheet Roll Forming Machine is a precision-engineered system designed for the efficient production of trapezoidal roofing sheets with superior surface quality and dimensional accuracy. It is ideal for industrial facilities, warehouses, commercial complexes, and residential roofing applications.

This machine processes PPGI, galvanized steel (GI), galvalume (GL), and aluminum coils with thicknesses ranging from 0.3mm to 0.8mm. Each sheet produced delivers a smooth finish, uniform shape, and long-lasting strength suitable for all-weather performance.

Equipped with an advanced PLC control system, hydraulic cutting technology, and up to 26 precision roller stations, the IBR Roof Sheet Making Machine guarantees stable operation, consistent forming accuracy, and a high output speed of 15–20 meters per minute.

Offering a perfect balance of efficiency, precision, and durability, this machine is an excellent solution for manufacturers aiming to produce high-quality metal roofing panels at scale.

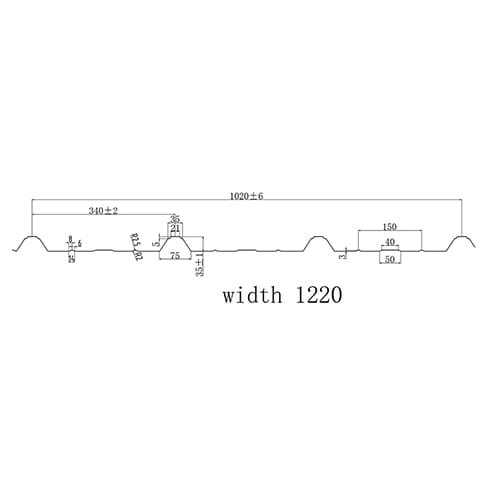

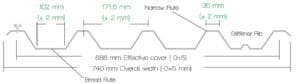

Product Profile Drawings

Technical Parameters

| Item | Specification Details |

|---|---|

| Applicable Materials | PPGI, GI, Aluminum, GL |

| Thickness | 0.3–0.8 mm |

| Coil width | 1000/1250 mm (customized per profile) |

| Decoiler | Hydraulic automatic decoiler (manual type provided as free option) |

| Forming Unit – Roller stations | 26 rows (adjustable per requirement) |

| Forming Unit – Shaft | Solid 80 mm, 45# steel, heat-treated |

| Forming Unit – Rollers | 45# steel, CNC processed, hard chrome-plated (HRC 55–60) |

| Forming Unit – Frame | 350# H-beam steel |

| Forming Unit – Transmission | Chain drive |

| Forming Unit – Dimension | 10500 × 1600 × 1600 mm (customized) |

| Forming Unit – Weight | Approx. 11.5T |

| Cutting System – Type | Hydraulic cutting, post-cut type |

| Cutting System – Blade material | Cr12Mov, anti-scratch, anti-deformation |

| Power & Control – Motor power | 5.5 kW |

| Power & Control – Hydraulic system | 5.5 kW |

| Power & Control – Voltage | 380V, 50Hz, 3 Phase (optional customization) |

| Power & Control – PLC & control cabinet | Famous brand, multilingual interface |

| Power & Control – Touch screen | User-friendly, supports batch setting, length, and quantity control |

| Production Speed | 15–20 m/min (depending on sheet thickness and profile) |

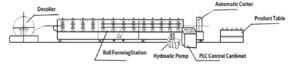

Flow Chart

Product Video

Application

Finshed Product