Introduction of Roll Forming Technology

Roll forming technology plays an essential role in modern metal manufacturing, especially in industries that require high-volume production with consistent profile accuracy. A roll forming machine gradually shapes metal coils into continuous profiles through a series of precisely engineered rollers, making it one of the most efficient forming methods for long-length metal components.

Today, roll forming technology is widely adopted by construction material manufacturers, steel structure suppliers, and industrial fabricators. With the support of experienced roll forming machine manufacturers, this technology has evolved into complete automated systems capable of meeting diverse market requirements.

Roll Forming Technology Overview

Roll forming is a continuous bending process in which flat metal strips are progressively formed into a desired cross-section. Unlike stamping or press braking, a roll forming line operates at stable speeds and produces minimal material waste.

A typical roll forming system consists of:

- Decoiler

- Leveling unit

- Roll forming machine

- Cutting system

- Run-out table or stacking system

This modular structure allows a roll forming line to be adapted for different applications by adjusting forming stations or tooling configurations.

Construction and Roofing Industry Applications

One of the most common applications of roll forming technology is in the construction and roofing industry. Products such as corrugated roofing sheets, standing seam panels, and metal cladding panels are all manufactured using roll forming machines.

For roofing applications, roll forming machines offer:

- High dimensional accuracy

- Uniform panel appearance

- Efficient mass production

Standing seam roofing panels, in particular, require precision rollers and stable forming pressure. A professionally designed roll forming line ensures tight seams and reliable installation performance, especially for commercial and industrial buildings.

Steel Structure and Building Systems

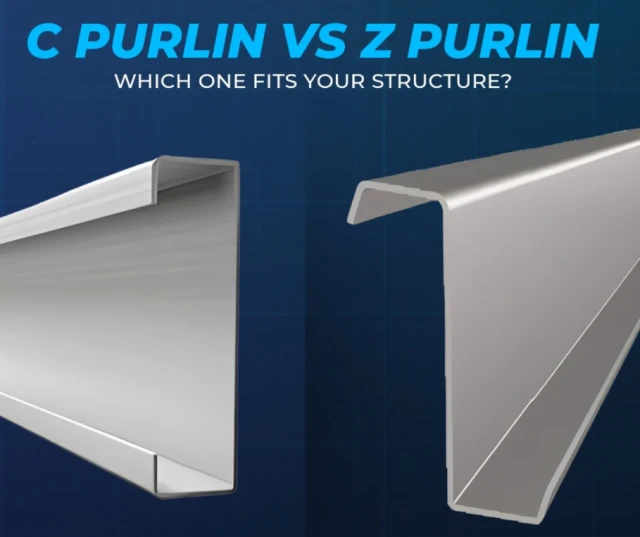

Roll forming technology is widely used in steel structure systems, including purlins, beams, and framing components. Profiles such as C purlins, Z purlins, and U channels are commonly produced using heavy-duty metal roll former equipment.

In these applications, roll forming machines must handle thicker materials and higher yield strength steel. Structural roll forming lines are often equipped with:

- Reinforced machine frames

- Larger shaft diameters

- Precision punching systems

These features allow manufacturers to meet strict structural requirements while maintaining production efficiency.

Metal Decking and Flooring Systems

Metal decking used for floors and composite slabs is another important application of roll forming technology. Deck profiles require tight tolerances to ensure proper concrete bonding and load-bearing performance.

A dedicated roll forming machine for metal decking typically includes:

- Multi-stage forming stations

- High-precision rollers

- Flying cutting systems for continuous operation

By using a complete roll forming line, manufacturers can achieve consistent profile geometry and reduce installation issues on construction sites.

Solar PV Mounting and Energy Systems

With the global growth of renewable energy, roll forming technology has become increasingly important in solar photovoltaic mounting systems. Steel profiles used for solar structures must meet specific strength and corrosion resistance standards.

Roll forming machines are well suited for producing:

- Solar mounting rails

- Support channels

- Custom structural profiles

Many solar component manufacturers work closely with a roll forming machine manufacturer to develop customized roll forming lines that meet local market standards and installation practices.

Industrial and Customized Profile Applications

Beyond standard construction products, roll forming technology is also used for customized industrial profiles. These include shelving systems, cable trays, fencing panels, and automotive components.

For customized applications, metal roll former systems are often designed with:

- Adjustable widths

- Interchangeable roller sets

- Flexible punching configurations

This adaptability allows manufacturers to respond quickly to changing customer requirements without replacing the entire roll forming machine.

Advantages of Roll Forming Technology Across Industries

Across all applications, roll forming technology offers several key advantages:

- Continuous production with stable output

- High material utilization and low scrap rates

- Consistent profile quality over long lengths

- Compatibility with automation and inline processing

When supported by an experienced roll forming machine manufacturer, these advantages translate into long-term production reliability and cost efficiency.

Conclusion

The applications of roll forming technology continue to expand as industries demand efficient, scalable, and precise metal forming solutions. From roofing and steel structures to solar energy systems and customized industrial components, roll forming machines provide unmatched flexibility and productivity.

By selecting the right roll forming line configuration and working with a reliable roll forming machine manufacturer, manufacturers can leverage roll forming technology to meet current market demands and support future growth.