مقدمة

C purlins and Z purlins are fundamental components in steel building construction, widely applied in light gauge steel framing, industrial warehouses, commercial buildings, and residential roofing. Selecting the right purlin profile is not only a matter of structural integrity but also directly influences installation efficiency, material cost, and long-term building performance. For manufacturers and contractors, understanding the subtle differences between C and Z purlins is essential to ensure optimal design and installation outcomes.

In modern construction projects, these profiles are produced using C/Z purlin roll forming machines, which allow for precise shaping, hole punching, and consistent quality across long production runs. This article provides an in-depth examination of structural differences, practical applications, installation considerations, and production insights, offering a comprehensive guide for engineers, builders, and equipment buyers.

Structural Differences

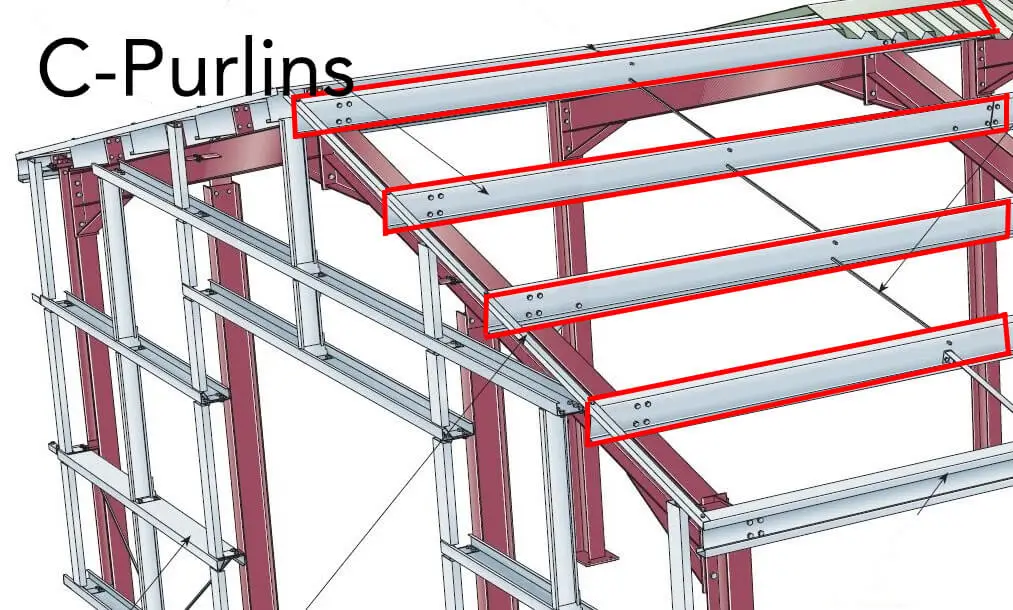

C Purlins

C purlins are shaped like the letter “C,” featuring a flat web with flanges on one side. Their design allows them to be stacked or mounted efficiently for short-span applications. Key structural characteristics include:

- Web and flange configuration: The flat web provides stiffness along the vertical axis, while the flanges offer surface area for bolting and attachment.

- Span suitability: C purlins are ideal for shorter spans where multiple supports can be installed at regular intervals.

- Connection ease: The flat flange surface simplifies fastening to rafters, girts, or supporting frames using screws or bolts.

- Support requirements: Long-span applications require additional supporting brackets to prevent deflection or bending under load.

C purlins are often selected for residential projects, small workshops, and warehouses where simplicity and rapid installation are critical. Using a C/Z purlin roll forming machine, manufacturers can produce these profiles with consistent thickness and precise dimensions, ensuring structural reliability and ease of installation.

Z Purlins

Z purlins feature a distinctive “Z” shape, with offset flanges that allow panels to nest and lap end-to-end, increasing structural efficiency for long-span applications. Their main structural characteristics include:

- Offset flange design: This enables easy nesting and continuous spanning, reducing the need for intermediate supports.

- Long-span suitability: Z purlins are preferred for industrial and commercial buildings with extended roof spans due to higher load-bearing capacity.

- Improved strength: Compared to C purlins of the same gauge steel, Z purlins offer enhanced bending resistance and stability under uniform loads.

- Continuous roofing systems: Ideal for multi-bay structures, the design minimizes connections and enhances structural continuity.

Modern C/Z purlin roll forming machines produce Z purlins with precise flange angles and hole positions, accommodating both standard and custom profiles to meet project-specific structural requirements.

Applications

C and Z purlins are selected based on project scale, load requirements, and installation preferences:

- C Purlins: Suitable for small to medium-sized structures, including workshops, warehouses, agricultural buildings, and light steel residential framing. Their design supports rapid installation and is cost-effective for projects where the span is limited and intermediate supports are available.

- Z Purlins: Optimal for large-span industrial warehouses, commercial facilities, and multi-bay roofing systems. The ability to lap and nest reduces the number of connections required, enhancing stability and reducing installation labor.

In all applications, using a C/Z purlin roll forming machine ensures uniform production quality, precise hole placement for bolts or fasteners, and repeatable profile dimensions that conform to engineering specifications.

Installation Considerations

Proper installation of C and Z purlins is essential for structural performance and longevity:

- C Purlins: Require more frequent support brackets due to their flat web design. Alignment is critical to ensure uniform load distribution and to prevent deflection. Fastening is straightforward, but installers must monitor span limitations closely.

- Z Purlins: Designed for overlapping and nesting, reducing the number of intermediate supports. This simplifies installation and provides continuous load transfer across the roof structure. Special attention is needed to align overlapping sections and secure connections.

Both C and Z purlins benefit from precision manufacturing on a C/Z purlin roll forming machine. The machines produce consistent dimensions, allowing for easier on-site alignment and reducing potential errors during installation.

Additional considerations for installation include:

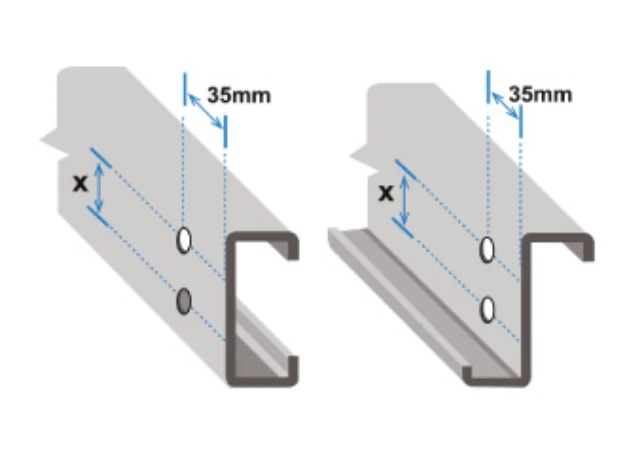

- Ensuring correct orientation of flanges to support roofing panels or secondary framing

- Verifying spacing between purlins to meet load requirements and local building codes

- Coordinating hole patterns for bolting to reduce field adjustments

Advantages of Using C/Z Purlin Roll Forming Machines

Modern C/Z purlin roll forming machines offer several benefits for both manufacturers and end-users:

- High precision and repeatability: Each profile maintains tight dimensional tolerances across long production runs.

- Integrated punching systems: Pre-punched holes for fasteners reduce on-site labor and increase installation speed.

- Customizable profiles: Machines can be adjusted to produce different flange widths, web heights, and thicknesses for project-specific requirements.

- Material efficiency: Minimal waste is generated, reducing production costs.

- Consistent quality: Cold roll forming preserves steel strength and ensures surface integrity, supporting long-term building performance.

These advantages make C/Z purlin roll forming machines indispensable for companies producing light gauge steel components for a wide range of construction projects.