مقدمة

Selecting the right آلة تشكيل اللفائف is a critical investment decision for companies involved in metal fabrication, construction materials, and steel structure manufacturing. A properly configured roll forming machine can significantly improve production efficiency, ensure consistent product quality, and reduce long-term operating costs.

For many buyers, working with an experienced مصنع آلات تشكيل اللفائف is just as important as selecting the machine itself. A reliable manufacturer can provide technical guidance, customization options, and long-term support that directly affect production stability.

This practical buyer’s guide explains the key factors to consider when choosing a roll forming machine based on real production requirements rather than short-term pricing.

1.Material Type and Thickness Requirements

Before evaluating any roll forming machine, buyers should clearly define the raw materials to be processed. Most roll forming machines and تشكيل المعادن بالدرفلة systems are designed to handle metal coils such as:

- Galvanized steel (GI)

- Pre-painted galvanized steel (PPGI)

- Aluminum

- Stainless steel

In addition to material type, it is essential to confirm:

- Material thickness range (for example, 0.3–0.8 mm or 1.0–3.0 mm)

- Coil width

- Yield strength of the steel

A roll forming machine designed for light-gauge roofing panels will differ significantly from a heavy-duty metal roll former used for structural profiles. Selecting equipment that matches actual material parameters helps prevent profile deformation, reduces roller wear, and extends machine service life.

2. Profile Design and Forming Complexity

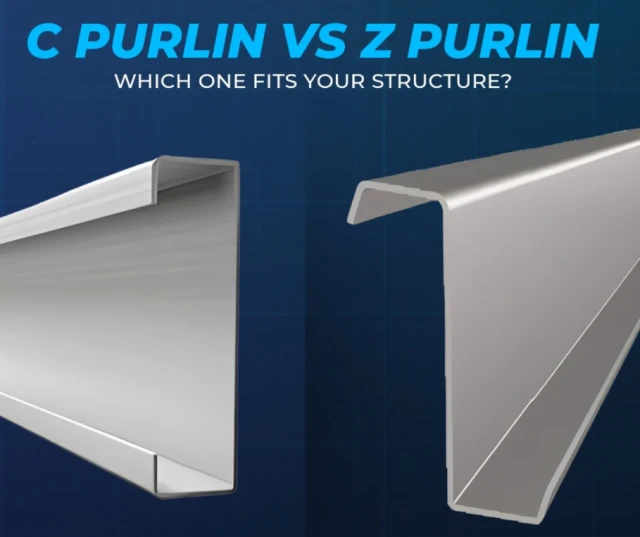

Profile design directly affects the configuration of a roll forming machine or complete خط تشكيل اللفائف. Simple profiles, such as corrugated sheets or standard C purlins, generally require fewer forming stations and simpler roller tooling.

In contrast, complex profiles—such as standing seam roofing panels, metal decking, or custom structural sections—often require:

- A higher number of forming stations

- Precision-machined rollers

- Additional straightening or leveling units

If product diversification is planned, buyers should consider a roll forming machine with adjustable width or interchangeable roller sets. This flexibility allows the same roll forming line to support multiple profile types with minimal downtime.

3. Production Speed and Output Capacity

Production capacity is another key factor when selecting a roll forming machine. Buyers should evaluate expected daily or monthly output, required line speed (meters per minute), and available labor resources.

High-speed automatic roll forming machines are commonly integrated into complete roll forming lines for continuous, large-scale production. For smaller factories or customized orders, semi-automatic machines or standalone metal roll former units may offer better cost control while still meeting quality standards.

Choosing a roll forming machine that aligns with real production demand avoids overinvestment and unnecessary energy consumption.

4. Automation Level and Control System

Modern roll forming machines are available with different automation levels, ranging from manual systems to fully automated roll forming lines. Common configurations include:

- Manual or semi-automatic roll forming line

- PLC-controlled automatic roll forming line

- Fully automated roll forming lines with servo punching, flying cutting, and auto stacking systems

Higher automation improves dimensional accuracy, reduces labor dependency, and enhances production consistency. For export-oriented manufacturers, an automated roll forming line is often preferred due to stable output and reduced human error.

5.Cutting System Selection

The cutting system used in a roll forming machine directly affects productivity and finished product accuracy. The most common cutting methods include hydraulic stop cutting and flying cutting.

Hydraulic stop cutting is suitable for lower-speed applications, while flying cutting allows continuous production without stopping the roll forming line. For manufacturers targeting higher output and precise length control, flying cutting is generally the more efficient solution.

6. Supplier Experience and After-Sales Support

Beyond technical specifications, the experience of the مصنع آلات تشكيل اللفائف plays a vital role in project success. A professional manufacturer should provide complete technical documentation, installation guidance, operator training, and reliable spare parts supply.

Working with an experienced roll forming equipment manufacturer reduces installation risks and ensures that the roll forming line operates smoothly throughout its service life.

خاتمة

Choosing the right metal roll former solution requires a balanced evaluation of material specifications, profile complexity, production capacity, automation level, and supplier reliability. Whether investing in a standalone metal roll former or a fully automated roll forming line, proper planning ensures long-term performance and consistent product quality.

By carefully assessing these factors, manufacturers can invest in a roll forming machine that supports sustainable growth and efficient production.