Máquina formadora de canales de enrasado

Para obtener más información, tiempos de entrega y precios, ¡envíenos un correo electrónico!

Descripción general del producto

The Stud Furring Channel Roll Forming Machine is a precision-engineered production system designed for manufacturing hat-shaped galvanized steel channels, a key component in modern wall and ceiling framing. These corrosion-resistant channels provide reliable support for gypsum panels and are typically installed perpendicular to masonry surfaces using specialized fasteners, suitable for both vertical and overhead applications.

Built for high efficiency and consistent output, the Stud Furring Channel Roll Forming Machine uses advanced roll-forming technology to produce uniform, durable channels at high speeds. Ideal for contractors and manufacturers, this machine improves productivity while maintaining the structural integrity and long-term performance of wall and ceiling systems in contemporary construction projects.

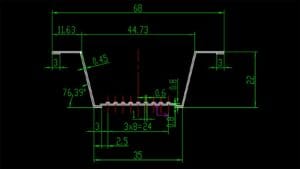

Dibujos de perfil de producto

Parámetros técnicos

| Artículo | Specification |

|---|---|

| Desenrollador | Manual decoiler |

| Inner Diameter (I.D) | 508–610 mm |

| Outer Diameter (O.D) | 1000–1200 mm |

| Decoiler Capacity | 3 Tons |

| Roll Diameter | 70 milímetros |

| Forming Roller Stations | 14 stations |

| Material del rodillo | 45# steel coated with hard chrome |

| Velocidad de formación | 0–12 m/min (excluding punching or cutting) |

| Machine Frame Stand | Welded structural steel |

| Thickness of Stand Plates | 18 mm |

| Main Power | 5.5 kW |

| Cutting Type | Hydraulic stop-to-cut |

| Hydraulic Power | 3 kW |

| Cutting Blade Material | Cr12 Steel with quenching treatment |

| Sistema de control | Japanese Panasonic PLC with inverter and Omron encoder |

| Voltaje | 380 V, 3-Phase, 50 Hz |

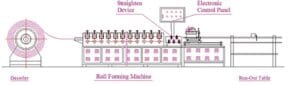

Diagrama de flujo de producción

Solicitud

Solicitud

Solicitud

Solicitud