Overview

Introduce roll forming machine solutions for metal profile manufacturing. A máquina formadora de rollos is an advanced metal forming system designed for the continuous production of precise and consistent metal profiles. By gradually shaping metal coils through a sequence of engineered rollers, roll forming machines enable manufacturers to achieve high efficiency, stable quality, and low material waste.

Como experimentado fabricante de máquinas perfiladoras, we provide a wide range of roll forming machine solutions for roofing systems, steel structures, flooring systems, and customized industrial profiles. Our roll forming machine solutions are widely used by metal fabrication companies, construction material manufacturers, and steel structure suppliers worldwide.

What Is a Roll Forming Machine?

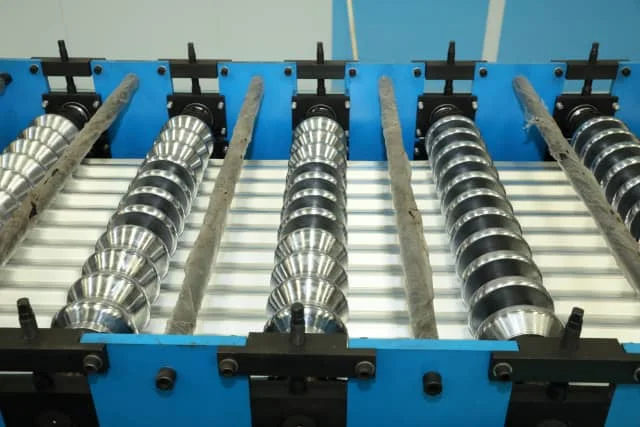

A roll forming machine is a type of metal processing equipment that converts flat metal coils into specific cross-sectional profiles through multiple forming stations. Unlike stamping or press braking, roll forming is a continuous process, making it ideal for long-length components and mass production.

A typical roll forming machine or complete línea de perfilado includes:

- Coil decoiler

- Leveling and guiding system

- Main roll forming machine

- Cutting system (hydraulic or flying cutting)

- Run-out table or automatic stacking system

This modular design allows roll forming machines to be configured for different applications and production requirements.

Applications of Roll Forming Machines

Roll forming machines are widely used across multiple industries due to their flexibility and efficiency.

Roofing and Cladding Systems

Roll forming machines are commonly used to produce corrugated roofing sheets, standing seam panels, and wall cladding panels. These products require consistent dimensions, smooth surface quality, and reliable forming accuracy.

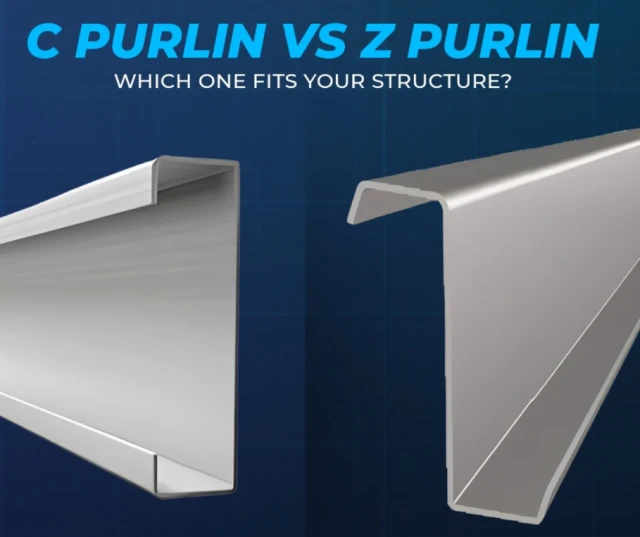

Steel Structure and Framing Systems

Structural profiles such as C purlins, Z purlins, and U channels are produced using heavy-duty perfiladora de metal equipment. These roll forming machines are designed to handle thicker materials and higher-strength steel.

Metal Decking and Flooring Systems

Metal deck roll forming machines produce floor deck and composite deck profiles used in industrial and commercial buildings. High-precision roll forming lines ensure tight tolerances and stable load-bearing performance.

Solar PV Mounting and Energy Systems

Roll forming machines are increasingly used to manufacture solar mounting rails and support structures. Customized roll forming line solutions help meet specific market standards and installation requirements.

Types of Roll Forming Machine solutions We Offer

To meet different production needs, we supply various roll forming machine configurations:

- Máquina formadora de láminas para techos

- Standing Seam Roll Forming Machine

- Purlin Roll Forming Machine (C / Z / U profiles)

- Máquina perfiladora de cubiertas metálicas

- Máquina para enmarcar acero de calibre ligero

- Customized Roll Forming Line Solutions

Soluciones para máquinas perfiladoras

Each roll forming machine can be tailored based on material thickness, profile complexity, production speed, and automation level.

Key Advantages of Our Roll Forming Machines

Working with a professional fabricante de máquinas perfiladoras ensures stable performance and long-term reliability. Our roll forming machines offer:

- Continuous production with high output efficiency

- Consistent profile accuracy over long production runs

- High material utilization and reduced scrap

- Compatibility with automated punching, cutting, and stacking systems

- Flexible configuration for standard and customized profiles

Whether you require a standalone metal roll former or a fully automated roll forming line, our solutions are designed to support scalable manufacturing.

Custom Roll Forming Machine Solutions

For customers with specific production requirements, we provide complete línea de perfilado customization services. Our engineering team works closely with clients to develop roll forming machines that match material specifications, profile designs, and output targets.

Customized roll forming machine solutions may include:

- Servo punching systems

- Flying cutting technology

- Automatic stacking and packaging

- Profile changeover solutions

This approach ensures that each roll forming machine integrates smoothly into existing production workflows.

Why Choose a Professional Roll Forming Machine Manufacturer?

Selecting the right roll forming machine manufacturer is just as important as choosing the machine itself. An experienced manufacturer provides not only equipment, but also technical expertise, installation guidance, and long-term support.

By working with a reliable roll forming machine manufacturer, manufacturers can reduce operational risks and achieve stable, efficient production over the full lifecycle of the roll forming machine.

Conclusión

Roll forming machines play a vital role in modern metal profile manufacturing, offering unmatched efficiency, flexibility, and production consistency. From roofing systems and steel structures to solar mounting and customized industrial profiles, roll forming machines support a wide range of applications.

By investing in the right roll forming machine and partnering with an experienced roll forming machine manufacturer, manufacturers can build a reliable production foundation and support long-term business growth.