Even with a well-designed máquina formadora de rollos en frío, production issues can occur if material conditions, tooling setup, or line parameters are not properly controlled. In high-volume manufacturing, small deviations can quickly lead to scrap, downtime, or customer complaints.

This article summarizes the most common problems in roll forming production and explains their causes and corrective actions using practical terminology familiar to roll forming operators, engineers, and equipment manufacturers.

Edge Wave

Description

Edge wave appears as rippling or waviness along the strip edges after forming. It is one of the most frequently encountered roll forming defects, especially in wide or thin-gauge profiles.

Common Causes

- Excessive compression at the strip edges

- Improper roll flower design

- Uneven material thickness or mechanical properties

- Insufficient leveling before forming

Practical Solutions

- Re-evaluate roll flower progression to balance forming forces

- Improve strip leveling and entry alignment

- Reduce over-forming in early stations

- Verify material consistency from the steel supplier

Bowing (Longitudinal Camber)

Description

Bowing refers to curvature along the length of the finished profile. This defect becomes more noticeable in long parts such as purlins or framing members.

Common Causes

- Uneven forming pressure between top and bottom rollers

- Misaligned forming stations

- Inconsistent strip feeding tension

Practical Solutions

- Check roller alignment and shaft parallelism

- Balance top and bottom roll engagement

- Stabilize decoiler tension and feeding system

Profile Twisting

Description

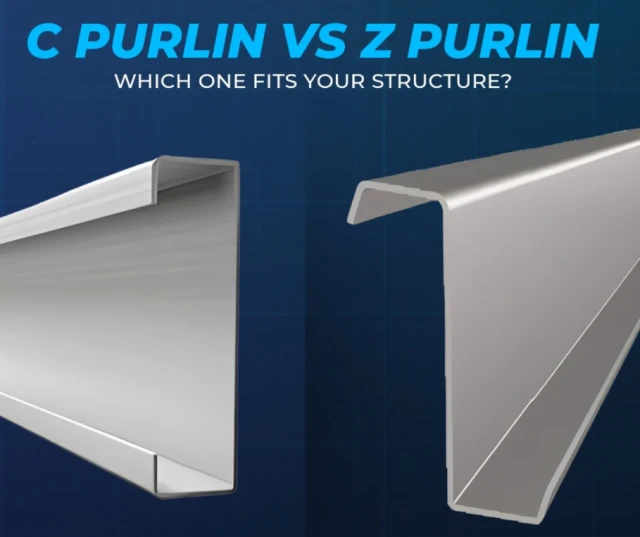

Twisting occurs when the profile rotates along its longitudinal axis during or after forming. This issue often affects asymmetrical sections such as Z purlins or complex custom profiles.

Common Causes

- Unbalanced roll design for asymmetrical profiles

- Incorrect side guide positioning n- Inadequate forming station quantity

Practical Solutions

- Optimize roll design for symmetry where possible

- Adjust side guides to maintain centerline control

- Add forming stations to distribute deformation more evenly

Length Deviation and Inaccurate Cut-to-Length

Description

Length deviation occurs when finished parts do not match the programmed cut length. This is critical in projects requiring precise installation alignment.

Common Causes

- Encoder slippage or incorrect calibration

- Inconsistent line speed during cutting

- Mechanical backlash in cut-off system

Practical Solutions

- Inspect and recalibrate length measuring encoders

- Use servo-driven flying cut-off systems for better accuracy

- Maintain cut-off mechanism and eliminate mechanical play

Punching Position Inaccuracy

Description

Punching inaccuracies result in misaligned holes or slots, affecting downstream assembly and installation.

Common Causes

- Punching not synchronized with line speed

- Strip slippage during punching

- Worn punching tools

Practical Solutions

- Synchronize punching with PLC-controlled line speed

- Improve strip clamping during punching

- Replace or regrind worn punch and die sets

Surface Scratches and Coating Damage

Description

Surface scratches or coating damage are unacceptable for visible applications such as roofing and cladding panels.

Common Causes

- Contaminants on rollers or strip surface

- Excessive roller pressure

- Poor handling at run-out table

Practical Solutions

- Clean rollers and entry guides regularly

- Reduce unnecessary forming pressure

- Improve run-out table design and profile handling

Inconsistent Profile Dimensions

Description

Dimensional inconsistency can appear as variation in flange width, web height, or angle.

Common Causes

- Roller wear or incorrect setup

- Material thickness variation

- Temperature effects during long production runs

Practical Solutions

- Monitor roller wear and schedule maintenance

- Verify incoming material specifications

- Implement periodic dimensional checks during production

Importance of System-Level Troubleshooting

Most roll forming problems are not caused by a single component but by system-level interactions. Effective troubleshooting requires evaluating the entire roll forming line, from decoiling and leveling to forming, cutting, and run-out handling.

Experienced roll forming machine manufacturers focus on integrated design and setup guidance to minimize these issues.

Conclusión

Common roll forming production problems such as edge wave, bowing, twisting, and length deviation can be effectively controlled with proper machine setup, tooling design, and process management.

By understanding the root causes and applying practical solutions, manufacturers can maintain stable output and consistent quality from their perfiladora de metal or complete línea de perfilado.