El roll forming process is a continuous metal forming method used to produce long, uniform profiles with consistent cross-sections. It is widely applied in construction systems, steel structures, roofing, decking, and light gauge framing industries.

Unlike press-based forming or stamping, cold roll forming relies on progressive bending through multiple roller stations, allowing steel strip to be shaped gradually with minimal internal stress. This makes roll forming particularly suitable for high-volume production where dimensional stability, surface quality, and repeatability are critical.

This article explains the roll forming process step by step, using terminology and workflow commonly used by experienced roll forming manufacturers and production engineers.

Overview of the Cold Roll Forming Process

At its core, the cold roll forming process transforms metal coil into finished profiles by passing the strip through a sequence of forming stations. Each station performs a small amount of deformation until the final shape is achieved.

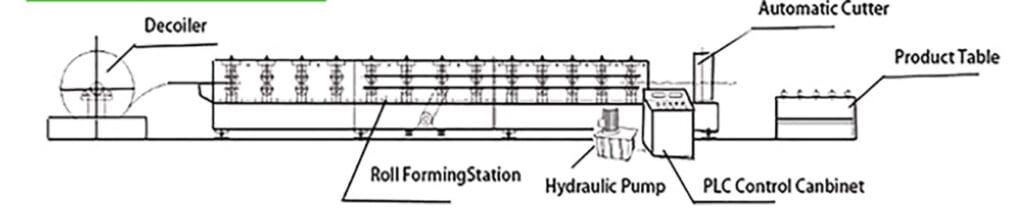

A typical línea de perfilado consists of:

- Decoiling and material feeding

- Leveling and strip preparation

- Pre-punching or inline punching (optional)

- Progressive roll forming

- Cutting System

- Run-out and stacking

Each stage plays a specific role in ensuring stable, high-quality output.

Step 1: Coil Feeding and Decoiling

The process begins with steel coil loading onto a decoiler. Depending on material thickness and coil weight, this may be a manual, hydraulic, or double-head decoiler.

Key considerations at this stage include:

- Coil inner diameter compatibility

- Stable coil rotation without jerking

- Controlled strip tension

In USA and European markets, hydraulic decoilers with hold-down arms are commonly specified to improve safety and feeding stability.

Step 2: Leveling and Strip Preparation

After decoiling, the strip passes through a leveling unit or straightener. The purpose is to remove coil set and residual stress before forming.

Proper leveling is critical because:

- Poor strip flatness leads to forming instability

- Edge wave and camber issues often originate here

- Punching accuracy depends on consistent strip alignment

For higher-precision applications such as metal deck or light gauge framing, multi-roll precision levelers are preferred.

Step 3: Pre-Punching or Inline Punching

Many roll formed products require holes, slots, or notches. These features are created using pre-punching units or inline punching systems integrated into the roll forming line.

Common punching configurations include:

- Hydraulic punching presses

- Servo-driven punching systems

- Mechanical presses for high-speed lines

Punching is synchronized with line speed and length control to ensure positional accuracy. In advanced lines, servo punching allows variable hole patterns without mechanical adjustment.

Step 4: Roll Forming Station

This is the core stage of the roll forming process. The strip passes through a series of forming stations, each equipped with upper and lower rollers designed according to a specific roll flower pattern.

Key principles of progressive forming include:

- Gradual bending rather than single-step deformation

- Balanced forming forces to avoid twisting

- Proper edge control to prevent buckling

The number of forming stations depends on profile complexity, material thickness, and tolerance requirements. Experienced roll forming machine manufacturers focus heavily on roll design accuracy at this stage.

Step 5: Cutting-Off- System

Once the final profile is formed, it is cut to length using a cut-off system. Two main cutting methods are used in roll forming lines:

- Flying cut-off: Cutting is performed while the line continues running, ideal for high-speed production

- Stop-to-cut: The line stops briefly during cutting, suitable for lower-speed or thicker material applications

Servo-driven flying cut-off systems are increasingly common due to their precision and reduced impact on profile quality.

Step 6: Run-Out, Stacking, and Packaging

After cutting, finished profiles are transferred to a run-out table or automated stacking system. Depending on production volume and labor strategy, this stage may be manual or fully automated.

Automated solutions can include:

- Length-based stacking

- Bundle counting systems

- Inline strapping or packaging

Efficient run-out handling reduces surface damage and improves overall line productivity.

Why Roll Forming Is Ideal for Mass Production

The cold roll forming process offers several advantages for mass production:

- Continuous operation with high output

- Excellent dimensional repeatability

- Minimal material waste

- Superior surface finish for coated steel

- Low per-unit production cost at scale

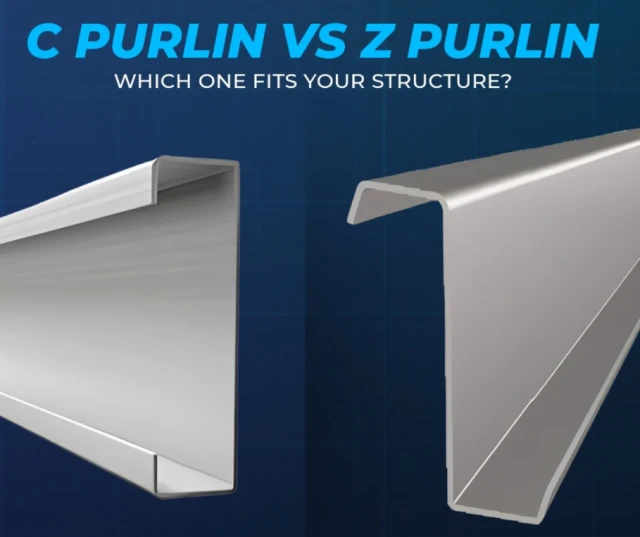

These advantages explain why roll forming is the preferred manufacturing method for roofing panels, metal decks, purlins, and structural framing profiles.

Roll Forming Process vs Other Metal Forming Processes

Compared with press brake forming or stamping, roll forming delivers:

- Better consistency over long lengths

- Lower labor dependency

- Improved coating protection

- Higher efficiency for standardized profiles

For these reasons, roll forming is rarely replaced once production volume increases beyond a certain threshold.

Conclusión

El proceso de conformado de rollos en frío is a proven and efficient manufacturing method for producing high-quality steel profiles at scale. From coil preparation to progressive forming and precision cutting, each stage contributes to the stability and efficiency of the final product.

By understanding how the roll forming process works in real production environments, buyers can make informed decisions when selecting a máquina formadora de rollos or complete línea de perfilado. This knowledge also helps align equipment investment with long-term production goals.