news

Company News

- Cangzhou Hener Machinery Co., Ltd, a professional roll forming machine supplier and roll forming machine factory, will participate in STEELFAB 2026 – Machinery, Technology & Equipment (21st Edition), held from January 12 to 15, 2026 at Expo Centre Sharjah, United Arab Emirates. 📍 Booth No.: 5-3237 STEELFAB is recognized as one of the most important […]/ December 20, 2025

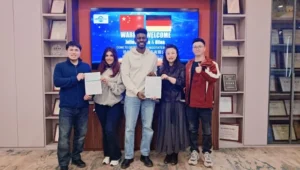

- Recently, our factory welcomed a customer from Germany who visited our production base for an on-site inspection and technical discussion. After a detailed evaluation of our equipment and manufacturing processes, the customer confirmed an order for a Stone Coated Metal Roof Tile Production Line, showing strong confidence in our product quality and service capability. During […]/ December 19, 2025

- Cangzhou Hener Machinery Co., Ltd., a global leader in roll forming equipment, has always adhered to the core values of “Innovation, Quality, and Service,” continuously advancing technology and optimizing products. Behind this progress is a highly skilled and experienced technical team. Since its establishment, Hener Machinery has focused on talent recruitment and development. The current […]/ November 12, 2025

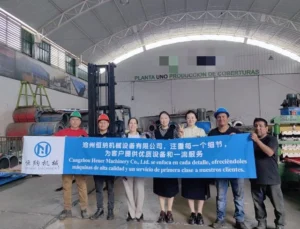

- Cangzhou Hener Machinery Co., Ltd. continues to solidify its position as a global leader in the manufacturing of roll forming machines, with a steadfast commitment to integrity, innovation, and quality. The company’s 40,000 square meter facility in Cangzhou, Hebei, is equipped with modern production lines, including advanced CNC machining centers and automated systems, ensuring the […]/ November 12, 2025

- Cangzhou Hener Machinery Co., Ltd., a leading manufacturer of roll forming equipment, is celebrating its 10th anniversary this year. Since its founding in 2010, the company has earned a strong reputation for providing high-quality, efficient, and durable machinery used in industries such as construction, steel structure manufacturing, logistics shelving, and prefabricated housing. Located in Cangzhou […]/ November 12, 2025

Product Updates

- In metal profile manufacturing, material cost often represents the largest portion of overall production expenses. Even small improvements in material utilization can lead to significant cost savings over long production runs. This is one of the key reasons why cold roll forming technology is widely adopted for high-volume, repeatable metal components. Compared with alternative forming […]/ January 16, 2026

- Light gauge steel framing (LGSF) has become a widely adopted construction system in residential, commercial, and modular building projects. Compared with traditional timber or concrete structures, light gauge steel framing offers consistent quality, dimensional accuracy, fast installation, and long-term durability. From a manufacturing perspective, LGSF relies heavily on cold roll forming technology. Studs, tracks, joists, […]/ January 16, 2026

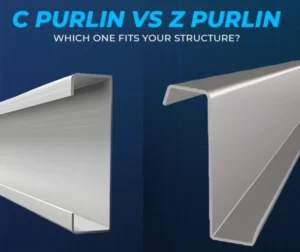

- C purlins and Z purlins are fundamental components in steel building construction, widely applied in light gauge steel framing, industrial warehouses, commercial buildings, and residential roofing. Selecting the right purlin profile is not only a matter of structural integrity but also directly influences installation efficiency, material cost, and long-term building performance. For manufacturers and contractors, […]/ January 9, 2026

- Correct roll forming machine installation guide is crucial for achieving stable, high-precision production. Improper setup can lead to defects, increased wear, and operational downtime. This guide explains step-by-step installation and commissioning practices used by experienced roll forming machine manufacturers. A well-prepared site reduces installation challenges and ensures safety. Proper leveling prevents profile twist, uneven wear, […]/ December 20, 2025

- The Africa market is rapidly expanding in metal construction and steel building components. Manufacturers require cold roll forming machines that are reliable, easy to maintain, and adaptable to varying power and material conditions. This article provides a practical guide for suppliers and buyers looking to optimize roll forming machine selection for Africa, focusing on operational […]/ December 20, 2025

- Even with a well-designed cold roll forming machine, production issues can occur if material conditions, tooling setup, or line parameters are not properly controlled. In high-volume manufacturing, small deviations can quickly lead to scrap, downtime, or customer complaints. This article summarizes the most common problems in roll forming production and explains their causes and corrective […]/ December 19, 2025

- The roll forming process is a continuous metal forming method used to produce long, uniform profiles with consistent cross-sections. It is widely applied in construction systems, steel structures, roofing, decking, and light gauge framing industries. Unlike press-based forming or stamping, cold roll forming relies on progressive bending through multiple roller stations, allowing steel strip to […]/ December 18, 2025

- Introduce the roll forming machine for USA Market. The United States is one of the most mature and demanding markets for cold roll forming machines. Buyers are typically experienced fabricators, construction system suppliers, or roll forming contractors who focus on long-term equipment reliability, compliance with industry standards, and stable high-volume output. Compared with emerging markets, […]/ January 9, 2026

- In the cold roll forming industry, profile design defines both the machine configuration and the final application. Unlike press-based forming, roll forming machines are optimized to produce long, constant cross-section profiles with high dimensional stability. These profiles are widely used in construction systems, industrial buildings, renewable energy structures, and light steel framing projects. Understanding common […]/ December 18, 2025

- Introduce roll forming machine solutions for metal profile manufacturing. A roll forming machine is an advanced metal forming system designed for the continuous production of precise and consistent metal profiles. By gradually shaping metal coils through a sequence of engineered rollers, roll forming machines enable manufacturers to achieve high efficiency, stable quality, and low material […]/ December 17, 2025

- Roll forming technology plays an essential role in modern metal manufacturing, especially in industries that require high-volume production with consistent profile accuracy. A roll forming machine gradually shapes metal coils into continuous profiles through a series of precisely engineered rollers, making it one of the most efficient forming methods for long-length metal components. Today, roll […]/ December 17, 2025

- Before evaluating any roll forming machine, buyers should clearly define the raw materials to be processed. Most roll forming machines and metal roll former systems are designed to handle metal coils such as: In addition to material type, it is essential to confirm: A roll forming machine designed for light-gauge roofing panels will differ significantly […]/ December 16, 2025

Our Services

Custom Design

Lifetime Services

Technical Training

Packaging and delivery