Máquina de perfilagem para o mercado africano

The Africa market is rapidly expanding in metal construction and steel building components. Manufacturers require cold roll forming machines that are reliable, easy to maintain, and adaptable to varying power and material conditions.

This article provides a practical guide for suppliers and buyers looking to optimize roll forming machine selection for Africa, focusing on operational flexibility, durability, and compatibility with local infrastructure.

Key Considerations for Africa Market

Power Supply and Electrical Adaptability

Many African countries have inconsistent voltage or frequency. Roll forming lines must be compatible with:

- 220V / 380V / 415V voltage options

- 50Hz / 60Hz frequency differences

- Robust motors capable of handling voltage fluctuations

Voltage stabilization and proper motor protection systems are essential.

Material Tolerance and Coil Quality

Steel coil quality varies widely in Africa. Machines should tolerate:

- Thickness variation

- Minor edge defects

- Variability in mechanical properties

Adjustable entry guides, forming station tolerances, and adaptable roll flower designs help maintain profile consistency despite material variation.

Simple Maintenance and Operation

Due to limited local technical support, machines must be easy to operate and maintain:

- Accessible lubrication points

- Simple hydraulic or pneumatic systems

- User-friendly PLC interface

- Standardized spare parts for quick replacement

This reduces downtime and ensures long-term reliability.

Common Applications

- Roof sheets and standing seam panels for residential and commercial buildings

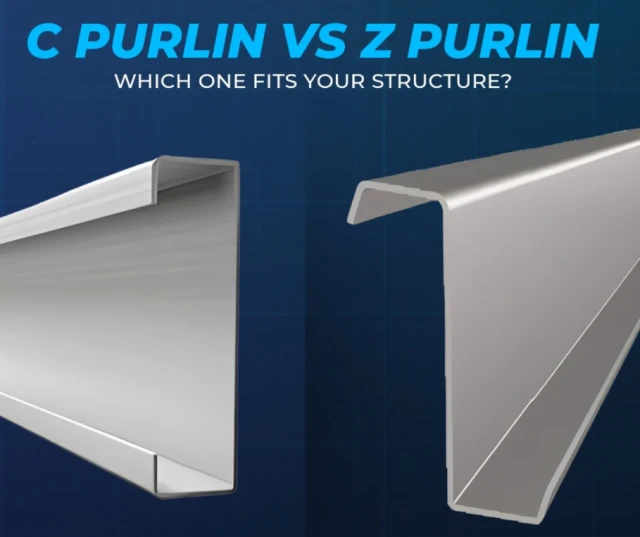

- C/Z purlins for steel framing and warehouse structures

- Light gauge steel components for prefabricated housing

These profiles are in high demand across multiple African regions.

Shipping and Installation Considerations

Due to long distances and variable infrastructure:

- Machines are often shipped in modular sections

- On-site assembly is required with minimal specialized tools

- Comprehensive documentation and remote guidance are valuable

These factors influence lead time and installation cost.

Conclusão

When selecting a roll forming machine for Africa, focus on adaptability, robust design, and ease of maintenance. Properly designed lines can handle local material and power variability, providing consistent output for roofing, framing, and prefabrication applications.