Introdução

Light gauge steel framing (LGSF) has become a widely adopted construction system in residential, commercial, and modular building projects. Compared with traditional timber or concrete structures, light gauge steel framing offers consistent quality, dimensional accuracy, fast installation, and long-term durability.

From a manufacturing perspective, LGSF relies heavily on cold roll forming technology. Studs, tracks, joists, and other framing members are produced using specialized light gauge steel roll forming machines, ensuring uniform profiles and repeatable tolerances across large production volumes.

This article explains how light gauge steel framing systems work, where they are commonly used, and why roll forming machines are essential for reliable LGS production.

What Is Light Gauge Steel Framing?

Light gauge steel framing refers to structural systems made from thin-gauge galvanized steel coils, typically ranging from 0.6 mm to 2.0 mm in thickness. These components are formed into precise shapes that provide structural strength while keeping overall building weight low.

Common LGSF components include:

- Wall studs

- Tracks (top and bottom runners)

- Floor joists

- Ceiling channels

- Bracing members

All of these profiles are manufactured on cold roll forming machines, which shape steel strip gradually through a series of forming stations without altering the material’s mechanical properties.

Key Advantages of Light Gauge Steel Framing

Dimensional Accuracy and Consistency

Unlike timber, steel does not warp, shrink, or twist over time. Roll forming ensures each framing member is produced to exact dimensions, which is critical for prefabrication and modular construction.

High Strength-to-Weight Ratio

Light gauge steel offers excellent load-bearing performance while remaining lightweight. This reduces foundation requirements and simplifies transportation and on-site handling.

Speed of Construction

Pre-punched holes and standardized profiles allow for fast assembly. Using framing components produced on LGS roll forming machines, installers can achieve shorter project timelines with fewer on-site adjustments.

Durability and Corrosion Resistance

Most LGS components are made from galvanized or coated steel, providing long-term protection against corrosion, moisture, and pests.

Manufacturing Process Using Roll Forming Machines

The production of light gauge steel framing components follows a continuous and controlled process:

- Decoiling: Galvanized steel coil is loaded onto the decoiler and fed into the line.

- Leveling and guiding: The strip is flattened and aligned before forming.

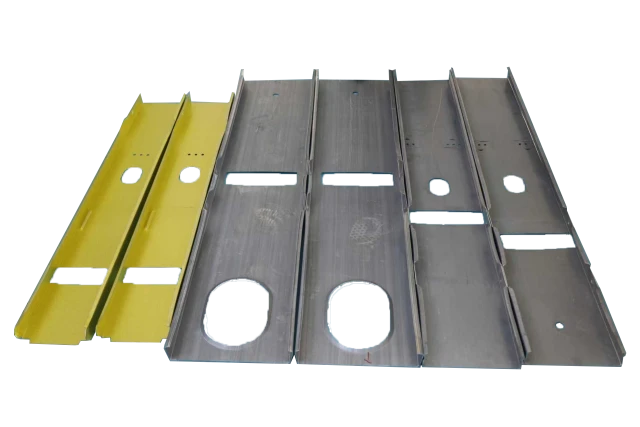

- Punching: Service holes, slots, and connection points are punched inline using hydraulic or servo punching units.

- Roll forming: The strip passes through multiple forming stations that gradually shape the steel into studs or tracks.

- Cut-to-length: Profiles are cut accurately using flying cut-off systems.

Common LGS Profile Types

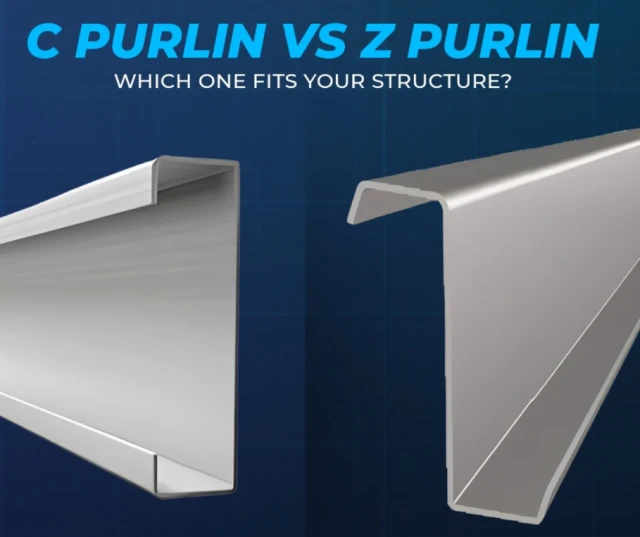

- C Studs: Primary vertical load-bearing members in wall systems

- U Tracks: Used as top and bottom runners to hold studs in place

- Floor Joists: Designed to support floor loads with optimized section geometry

- Hat Channels: Used for furring and ceiling systems

Each profile requires specific roll tooling and punch layouts, which can be customized on advanced cold roll forming machines.

Applications of Light Gauge Steel Framing

Light gauge steel framing is widely used in:

- Residential housing and apartments

- Commercial office buildings

- Schools and healthcare facilities

- Modular and prefabricated construction

- Temporary and permanent site offices

Its compatibility with BIM design and prefabrication makes LGSF particularly attractive for modern construction methods.

Why Roll Forming Quality Matters in LGSF

Because LGS components are assembled with tight tolerances, any dimensional deviation can affect wall alignment, panel fit, and structural performance. High-quality roll forming machines ensure:

- Accurate profile geometry

- Consistent hole positioning

- Minimal material stress

- Smooth surface finish

Experienced manufacturers invest in precision roll tooling, stable drive systems, and advanced PLC controls to maintain consistent output.

Light gauge steel framing is a proven, efficient construction system that relies on precision manufacturing. Using professional cold roll forming machines, manufacturers can produce reliable framing components that meet modern building standards and support fast, high-quality construction.

Understanding LGSF from both a structural and manufacturing perspective helps builders, developers, and equipment buyers make informed decisions when selecting light gauge steel roll forming solutions.