Introdução

In metal profile manufacturing, material cost often represents the largest portion of overall production expenses. Even small improvements in material utilization can lead to significant cost savings over long production runs. This is one of the key reasons why cold roll forming technology is widely adopted for high-volume, repeatable metal components.

Compared with alternative forming methods, roll forming offers a continuous and highly controlled process that minimizes waste while maintaining consistent profile geometry. This article explains how roll forming improves material utilization, the technical factors behind it, and why modern roll forming machines are preferred by manufacturers focused on efficiency and cost control.

Continuous Forming vs Batch Processing

One of the primary advantages of roll forming lies in its continuous production nature. Steel strip is fed directly from coil into the roll forming line, shaped gradually through multiple forming stations, and cut to length without interruption.

In contrast, batch processes such as press braking or stamping typically require:

- Individual blank cutting

- Multiple handling steps

- Higher trim loss

Continuous roll forming eliminates unnecessary cutting and handling, allowing nearly the entire coil width to be converted into finished product.

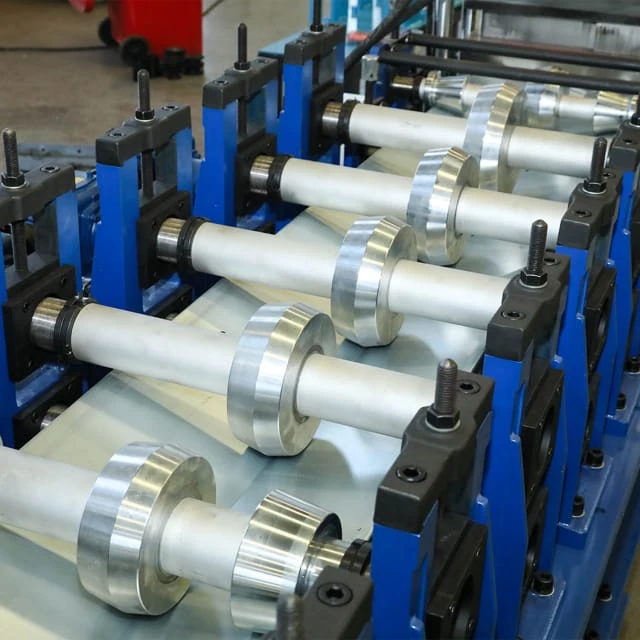

Precise Control of Strip Width and Thickness

Roll forming profiles are designed to match the exact width of the incoming coil. Because the process does not require trimming during forming, edge scrap is virtually eliminated.

Key factors include:

- Accurate coil width selection

- Optimized roll flower design

- Consistent material thickness control

Moderno cold roll forming machines maintain stable strip guidance and forming pressure, ensuring that material deformation is controlled rather than excessive.

Gradual Deformation Reduces Material Stress

Unlike press forming, which applies high force in a single operation, roll forming shapes material gradually across multiple stations. This controlled deformation:

- Preserves material strength

- Prevents cracking or tearing

- Reduces the need for oversized blanks

As a result, manufacturers can use thinner gauges without compromising structural performance, directly improving material utilization.

Inline Punching Minimizes Waste

Many roll formed profiles require holes, slots, or notches. With inline punching systems, these features are created during the forming process rather than as a separate operation.

Benefits include:

- Elimination of secondary processing

- Reduced scrap from misaligned punching

- Higher positional accuracy

Integrated punching units on roll forming machines are synchronized with line speed, ensuring efficient material usage.

Optimized Cut-to-Length Accuracy

Material waste often occurs when length accuracy is inconsistent. Advanced roll forming lines use servo-controlled flying cut-off systems to maintain precise cut lengths.

Accurate cutting:

- Reduces off-spec parts

- Prevents accumulation of unusable short sections

- Improves overall yield

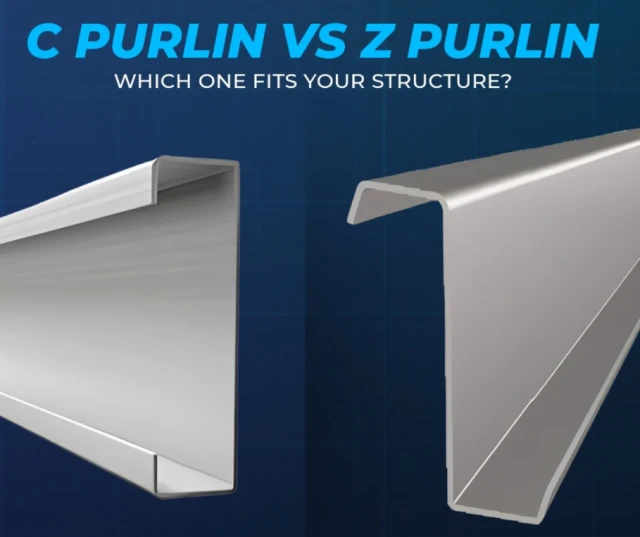

This is particularly important in long-run production such as purlins, framing members, and roofing panels.

Scrap Reduction Through Stable Process Control

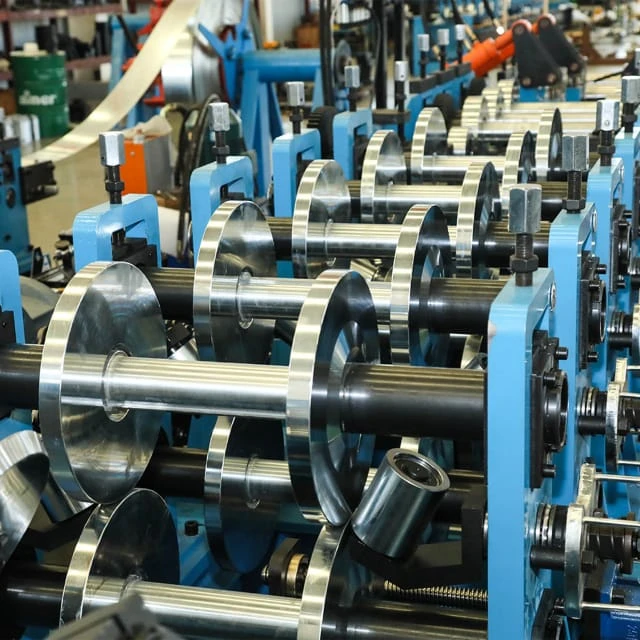

A stable roll forming process produces fewer defective parts. Key contributors include:

- Rigid machine frames

- Precision roll tooling

- Stable drive systems

- PLC-controlled line parameters

By maintaining consistent forming conditions, manufacturers minimize start-up scrap and reduce waste during speed changes or material transitions.

Comparison with Alternative Forming Methods

When compared to press brake forming or stamping:

- Roll forming generates less trim waste

- Material thickness can be optimized

- Finished profiles require fewer secondary operations

This makes roll forming particularly suitable for high-volume, standardized profiles where material efficiency directly impacts profitability.

Long-Term Cost Benefits

Improved material utilization translates into:

- Lower raw material cost per unit

- Reduced scrap handling and disposal

- Higher overall equipment efficiency

Over time, these benefits significantly improve return on investment for manufacturers operating cold roll forming machines.

Conclusão

Roll forming improves material utilization through continuous production, precise strip control, gradual deformation, and integrated processing. By reducing scrap and maximizing usable material, roll forming machines enable manufacturers to achieve consistent quality while lowering production costs.

For companies focused on efficiency and scalability, investing in advanced cold roll forming technology is a strategic decision that delivers long-term value.