Linha de produção automática de painéis sanduíche de EPS

Para mais informações, prazos de entrega e preços, envie-nos um e-mail!

Visão geral do produto

O Linha de produção automática de painéis sanduíche de EPS is an advanced, fully integrated system for continuous and high-quality panel manufacturing.

It produces durable sandwich panels made of two metal face sheets bonded to a lightweight EPS insulating core, offering strength, rigidity, and excellent thermal performance.

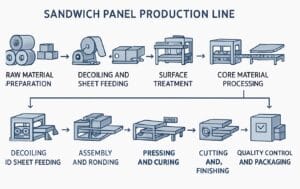

Automatic EPS Sandwich Panel Production Line integrates all key processes into one streamlined workflow:

uncoiling and film covering, precision roll forming, automated cutting, preheating, high-pressure foam application, double-belt conveying, controlled heating, and final panel cutting.

Engineered for stable operation and high productivity, the Linha de produção automática de painéis sanduíche de EPS ensures uniform panel quality with minimal manual handling.

It is ideal for large-scale industrial construction, cold room facilities, modular buildings, and energy-efficient architectural projects.

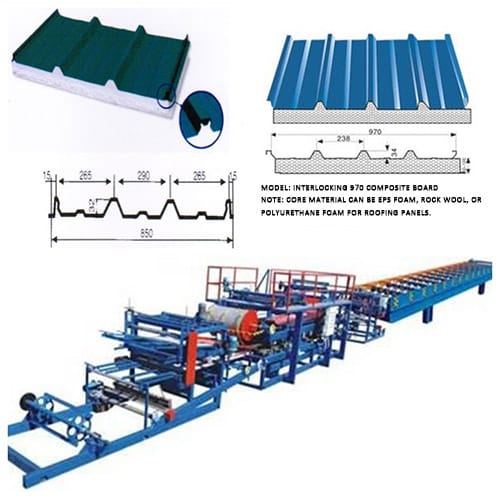

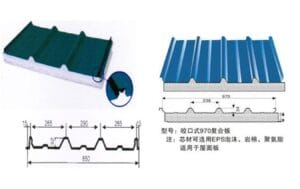

Desenhos de perfil do produto

Parâmetros técnicos

| Series | Detalhes | Parâmetro |

|---|---|---|

| Product Sheet | Raw material | GI/PPGI |

| Espessura do material | 0.18-0.8 mm (0.18-0.3 mm: hard material HRB65; 0.3-0.7 mm: soft material) | |

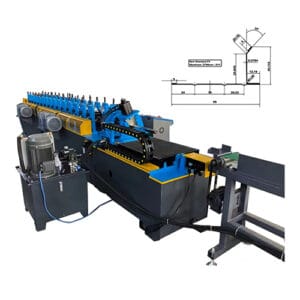

| Roll Forming Machine | Feeding device | Platform width adjustable by hand wheel; built-in bearing to protect steel sheet edges |

| Rolling Shaft – Material | 45# STEEL | |

| Rolling Shaft – Diameter | 70 mm | |

| Rolling Shaft – Treatment | Tempering treatment (prevents deformation and improves hardness) | |

| Roller – Material | 45# steel | |

| Roller – Treatment | Chromed treatment (Cr thickness: 0.05 mm; anti-corrosion, hardness enhancement, precision guarantee, good abrasion performance) | |

| Rolling Station | 3 stations (feeds steel sheet to pressing system) | |

| Machine Structure | Estrutura soldada da placa intermediária | |

| Machine Basic Frame | 350# H steel welded with internal diagonal bracing | |

| Consequência | Harbin, famosa marca chinesa. | |

| Work Power | 3 kW | |

| Roller Spacer & Pull Rod | Anti-rusty treatment |

Fluxograma

Exibição de detalhes do produto

Aplicativo

Produto final