Introduction

Introduce the roll forming machine for USA Market. The United States is one of the most mature and demanding markets for cold roll forming machines. Buyers are typically experienced fabricators, construction system suppliers, or roll forming contractors who focus on long-term equipment reliability, compliance with industry standards, and stable high-volume output.

Compared with emerging markets, USA customers place greater emphasis on engineering details, automation level, safety compliance, and lifecycle cost rather than just initial machine price. Understanding these expectations is critical for anyone supplying or configuring a roll forming machine for USA market.

Key Characteristics of the Roll Forming Machine For USA Market

Preference for Systemized Roll Forming Lines

In the USA, buyers rarely purchase a standalone roll former. Instead, they prefer a complete roll forming line that integrates:

- Hydraulic or servo decoiler

- Precision leveling unit

- Pre-punching or inline punching system

- Main roll forming mill

- Servo-driven flying cut-off

- Run-out table or automated stacking

This systemized approach reduces labor dependency and ensures consistent quality across long production runs.

Focus on Automation and Labor Efficiency

Due to higher labor costs in North America, USA manufacturers prioritize automation and production efficiency. Modern roll forming lines supplied to this market typically feature:

- PLC control systems with HMI interfaces

- Recipe-based profile changeover

- Automatic length measurement and correction

- Servo motors for punching and cutting accuracy

Manual adjustments and operator-dependent processes are increasingly avoided, especially in high-volume production environments.

Common Roll Forming Applications in the USA

Standing Seam Roofing Systems

Standing seam panels are one of the most established roll formed products in the USA construction industry. These profiles are produced using standing seam roll forming machines with precise seam geometry to meet weather-tightness and structural performance requirements.

Typical characteristics include:

- Consistent seam height and lock tolerance

- Compatibility with mechanical seaming tools

- Protection of pre-painted steel coatings

Applications:

- Commercial and industrial buildings

- Residential metal roofing

- Architectural roofing projects

Trapezoidal Roofing System

Popular profile drawings of roof sheet

- R Panel

- PBR Panel

- AG Panel

- 5V Metal Roof Panel

- MAX Rib Panel

- Multi-Rib Panel

Applications:

- Industrial roofing

- Residential metal roofing

- Architectural roofing projects

- Agricultural and storage facilities

Metal Deck (Floor Deck and Roof Deck)

Metal deck is widely used in steel-framed commercial buildings across the USA. These profiles are produced on metal deck roll forming machines designed to handle high-strength galvanized steel with tight tolerance control.

USA buyers typically require:

- Compliance with SDI deck profiles

- Stable rib depth and pitch

- High forming rigidity to prevent camber and twist

Applications:

- Commercial office buildings

- Parking structures

- Industrial facilities

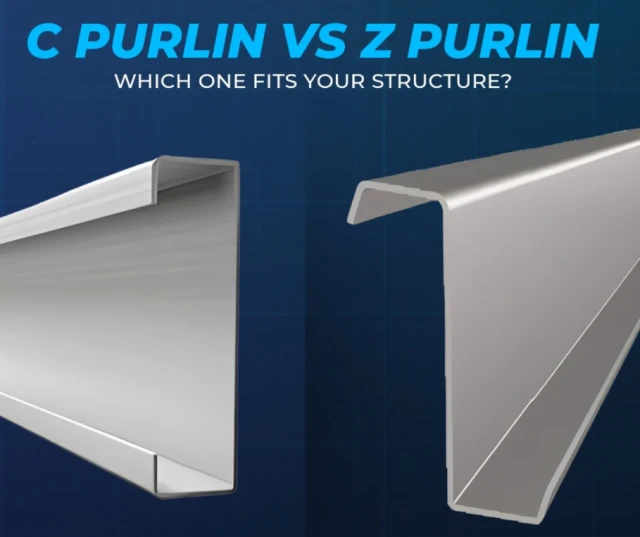

Light Gauge Steel Framing (LGSF)

Light gauge steel framing systems are increasingly popular in the USA for both residential and commercial construction. Profiles such as studs, tracks, and joists are produced using light gauge steel framing roll forming machines.

These lines often integrate:

- Servo punching for service holes

- Inline labeling or inkjet marking

- High-speed forming with minimal profile distortion

Applications:

- Prefabricated housing

- Modular construction

- Interior wall systems

Industry Standards and Compliance Expectations

USA buyers are highly sensitive to industry standards and compliance. While roll forming machines themselves are not always certified to a single mandatory standard, the profiles they produce must align with relevant specifications.

Commonly referenced standards include:

- ASTM standards for steel material properties

- AISI specifications for cold-formed steel members

- SDI standards for metal deck profiles

- UL requirements for certain building systems

Roll forming machine manufacturers supplying the USA market must design equipment capable of maintaining consistent profile dimensions within these specifications.

Machine Design Considerations for the USA Market

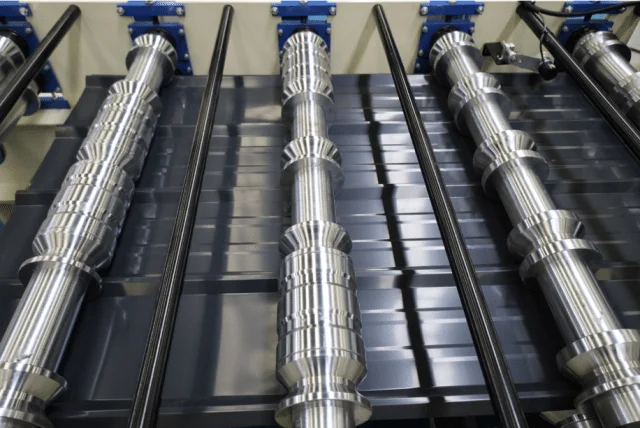

Forming Accuracy and Stability

USA customers expect long-term dimensional consistency. This requires:

- Proper roll flower design

- Adequate number of forming stations

- High-precision roller machining and heat treatment

Cost-driven designs with insufficient forming passes often lead to edge wave, bowing, or twisting—issues that are unacceptable in this market.

Typical Buyer Profile in the USA

USA buyers of roll forming machines are usually:

- Established roll forming contractors

- Building system manufacturers

- Roofing and decking product suppliers

- OEM manufacturers serving construction markets

These buyers focus on total cost of ownership, including maintenance, downtime, and upgrade potential, rather than short-term savings.

Conclusion

Supplying a roll forming machine for the USA market requires more than basic forming capability. Buyers expect engineered solutions that deliver accuracy, automation, safety, and long-term reliability.

By aligning machine design with USA market applications, industry standards, and operational expectations, manufacturers can build strong, long-term partnerships with North American customers. A well-designed metal roll former or integrated roll forming line is not just a piece of equipment—it is a core production asset in competitive manufacturing environments.