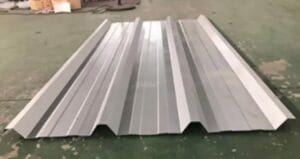

Машина для производства трапециевидных кровельных панелей PV4

Для получения дополнительной информации, сроков доставки и цен, пожалуйста, напишите нам!

Обзор продукта

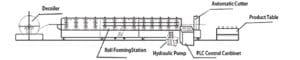

The Машина для производства трапециевидных кровельных панелей PV4 is engineered for producing PV4 and PV5 trapezoidal metal roofing sheets with high dimensional accuracy and clean, uniform surface profiles. Designed for efficient continuous forming, PV4 Trapezoidal Roof Panel Machine provides manufacturers with a dependable solution for high-volume roof panel production.

Built on a reinforced steel frame and equipped with precision-machined rollers, the machine delivers stable forming performance even under long operating cycles. The integrated PLC control system ensures precise synchronization throughout the line, helping maintain consistent panel quality and reducing adjustment time during production.

Suitable for residential, commercial, and industrial building projects, the PV4 Trapezoidal Roof Panel Machine allows producers to create strong, durable, and visually appealing roof panels that meet modern construction standards. Its reliable output, smooth finish, and long service life make it a valuable asset for roofing material manufacturers seeking improved efficiency and accuracy.

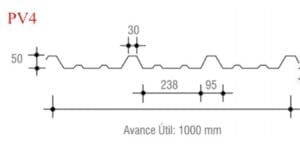

Чертежи профиля продукта

Технические параметры

| Number of rows | 18 Rows |

| Скорость | 15m/min |

| Cutting knife material | Cr12Mov |

| Roller diameter | Φ70mm |

| Dimensions | About 8.5 * 1.4 * 1.6 m |

| Масса | About 6.8 tons |

| Main structure of the machine | 350H beams/450H beams (according to your needs) |

| Transmission mode | Chain drive |

| Chain size | 1.2 inches |

| Side panel | 16 mm |

| Напряжение | 380 V 50 Hz three-phase or according to your needs |

| Control system | PLC control |

| Processing precision | Within 1.0 mm |

| Driving mode | Motor driver |

| Power | 5.5kw+4kw |

| PLC language | Chinese + English + According to your local language |

| Rolling stock | Forged #45 steel with chrome plate |

| Length tolerance | ±2 mm |

| Thickness | 0.3-0.8 mm |

| Ширина катушки | 1200/1220mm |

Схема технологического процесса производства

Готовый продукт